Dairy processing – an overview

Practical Action

All internal walls should be plastered or rendered with concrete that has no cracks that could

harbour dirt or insects. The lower parts of walls should either be tiled to at least 1.5 metres

above the floor, or painted with waterproof white gloss paint. Higher parts of walls can be

painted with good quality emulsion paint if tiling is too expensive. Windows should be screened

with mosquito mesh. Thin metal chains, or strips of plastic can be hung from door lintels to

deter flying insects, or alternatively, mesh door screens can be fitted. The floor should ideally be

tiled with floor tiles. However, these are expensive and may be slippery when wet. Good quality

concrete, smooth finished and without cracks can be used instead. Vinyl-based floor paints can

be used to protect floors, but they are expensive. Red wax household floor polishes should not be

used because they wear away easily and could contaminate products.

Proper drainage prevents pools of stagnant water forming, which would allow insects and micro-

organisms to breed. The floor should have a 2-3% slope to drain water to a drainage channel,

which is covered with a metal grating that can be removed to clean the drain. A wire mesh cover

should be fitted over the drain exit to prevent rodents and crawling insects getting into the

building through the drain. This should also be easily removed for cleaning.

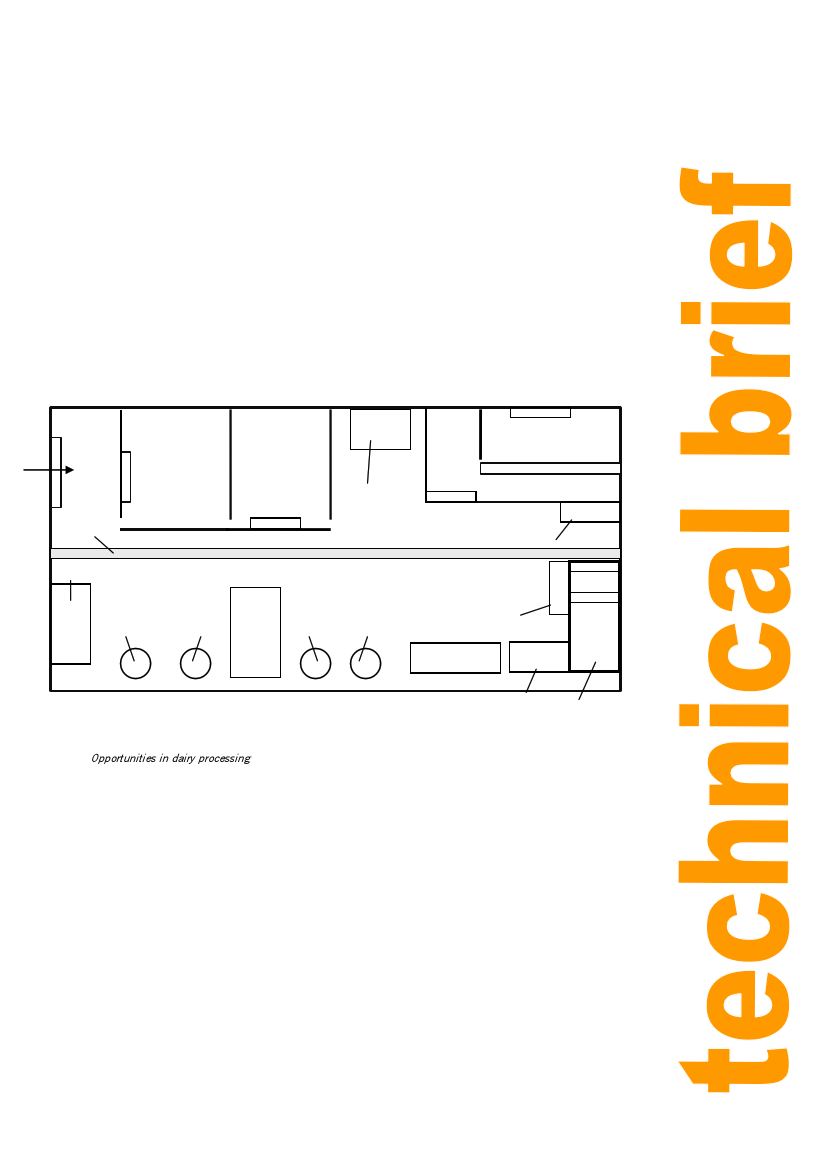

Milk in

Milk cold store Product cold

store

Office/Retail sales

Drain

Yoghurt

incubator

Spares and tools

QA testing

Cream Butter Cheese Cheese Boiling

separator churn vat

press pan

Cleaning

materials

Packaging

Figure 1: Layout of a small dairy

From: Opportunities in dairy processing

Packaging store

Washroom & toilet

An adequate supply of clean water of drinking quality should be available from taps in the

processing room (2-5 litres of water are required to process one litre of milk at a small scale of

operation). Hosepipes with pistol grip adjustable sprays should ideally be used for washing down

floors and equipment. If necessary, water should be treated to remove bacteria. The cheapest

and easiest way is to use bleach (also known as ‘chlorine solution’ or ‘hypochlorite’). Bleach is

cheap and effective against a wide range of micro-organisms. Water for cleaning should contain

about 200 ppm (mg/litre) of chlorine, made by mixing 1 litre of bleach into 250 litres of water.

Commercial treatment units that use ultra-violet light to destroy micro-organisms in water are

suitable for larger-scale processors that use a lot of water.

Equipment

All dairy equipment should be designed and constructed so that it can be easily dismantled for

cleaning (e.g. there should be no blank ends to pipework that would harbour stagnant milk).

Mixing bowls, boiling pans etc. should have a smooth internal surface without corners, and all

welds should be ground to a smooth finish. Ideally, all dairy equipment should be made from

stainless steel, but alternatives include polished aluminium, or food grade plastic for containers

and equipment that are not heated. Mild steel cannot be used because it will rust and

2